【Applicable Equipment】

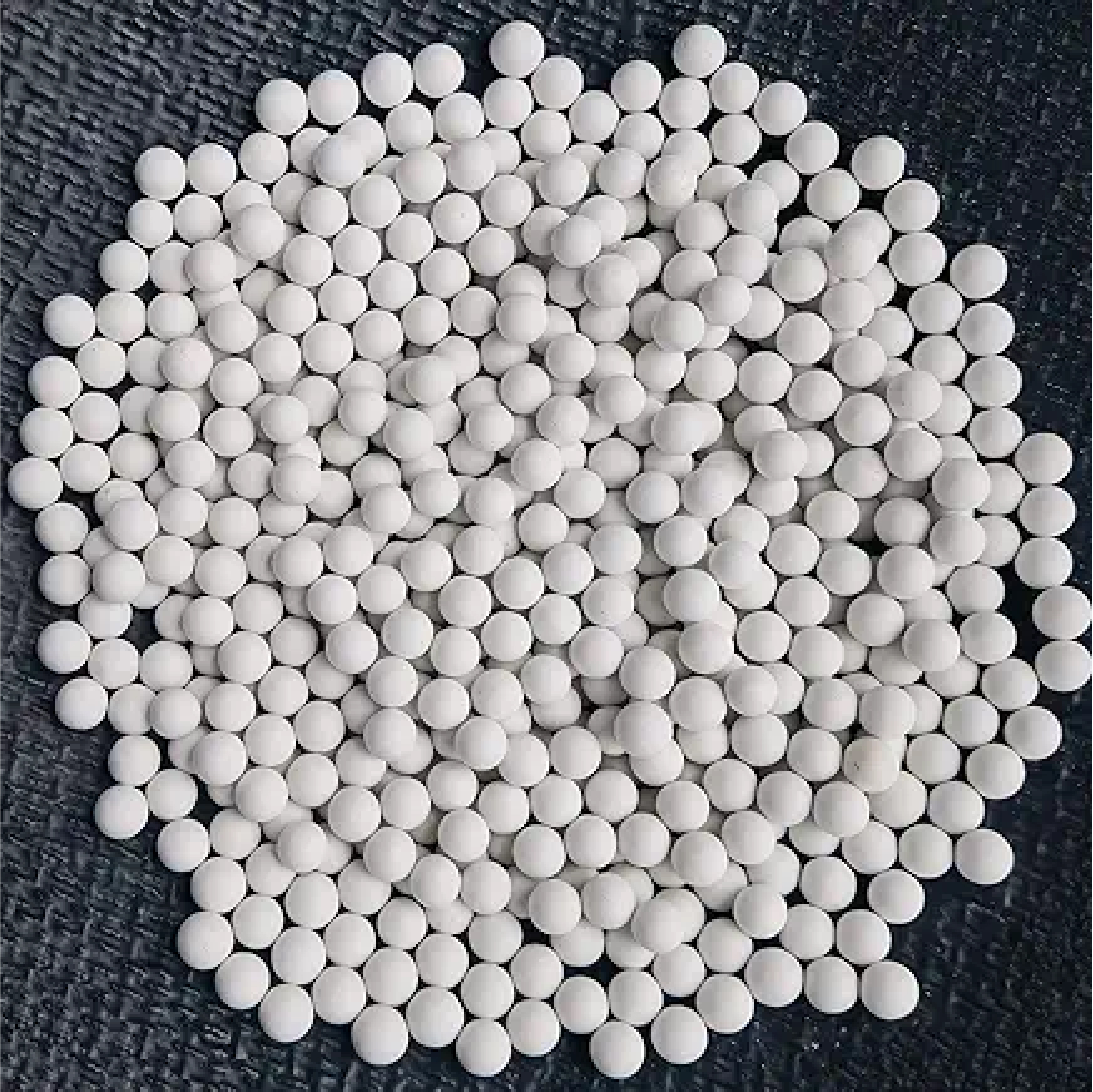

Suitable for ball mills, stirred mills, peeling machines, polishing machines, sand mills (such as E-Sand Mills), and various other grinding equipment.

【Product Features】

【Applications】

Widely used in industries such as non-ferrous metal mining, industrial ceramic powder, non-metallic powder, titanium dioxide, paper making, coatings, ink, and other powder materials. Suitable for use in ball mills, stirred mills, peeling machines, polishing machines, and sand mills.

| HCGA280 | HCGA320 | HCGA360 | HCGA370 | HCGA375 | |

|---|---|---|---|---|---|

| Al2O3(%) | 60±0.5 | 75±0.5 | 92±0.5 | 90±0.5 | 95±0.5 |

| Mohs Hardness | 7 | 8 | 9 | 9 | 9 |

| Bulk Density (g/cm³) | >2.8 | >3.2 | >3.6 | >3.7 | >3.7 |

| Wear Rate ‰ | <0.2 | <0.15 | <0.1 | <0.05 | <0.1 |

| Diameter Size | Φ1-10mm | Φ1-10mm | Φ0.5-60mm | Φ1-30mm | Φ1-60mm |

To ensure high-quality, durable, and wear-resistant ceramic grinding media, our production process follows a strict and precise sequence of steps:

1. Raw Materials: Select high-quality raw materials to ensure stable product performance.

2. Ultrafine Processing of Raw Materials: Utilize advanced technology for ultrafine processing, enhancing uniformity and purity.

3. Spray Drying: Apply spray drying techniques to form uniform granules for easy shaping.By following this rigorous production process, we ensure that our ceramic grinding media delivers exceptional wear resistance, high hardness, and outstanding performance in various grinding applications, including ball mills, stirred mills, sand mills, and polishing machines.

We will contact you with in 24 hours.